Delay and Disruption

Delay and Disruption are often cited as being the same issue. However a project or work activity can be disrupted but still complete as planned, or be delayed and not disrupted, such as in a later start date.

It is therefore necessary to distinguish the 2.

Delay

In a single activity, any delay to it would usually result in its completion being later. However most projects are complex and activities have an interlinked relationship consisting of dependencies and successors. A delay to one activity may not manifest itself to have an effect on the end date, this is the concept of float.

Therefore to determine what constitutes a delay to the completion date, a technique known as the Critical Path Method ("CPM") is used. This method calculates the reduction of float on all activities and therefore any impact on the end date or intermediate milestones. This can be as simple as updating the programme with actual progress or impacting the programme with events that have occurred that were not contemplated when the programme was produced and approved.

This is called Delay Analysis.

Delay Analysis can be either retrospective or prospective.

- Retrospective analysis involves the interpretation of the actual events that occurred when compared to those that were anticipated to happen.

- Prospective analysis involves the impacting of previously unforeseen events and determining the affect on the future time related aspects of a contract.

In both situations the objective is to apportion the responsibility to the correct party. However the correct party can only be determined from a review of the contract conditions.

Most standard form contracts do not deal specifically with the method of calculating the duration of culpability and/or entitlement. Therefore unless there is a specific amendment or it is described in the preliminaries then alternative authorities are required.

There are methods that have been accepted by the courts

to provide such calculations based on techniques from

notable bodies

The Society of Construction Law ("SCL") Delay and Disruption Protocol is a notable reference of delay analysis methods in the UK. It can be downloaded free via their website here.

The Association for the Advancement of Cost Engineering is another source of reference for Delay Analysis and Forensic Planning.

The choice of technique requires a reasoned assessment of the actual situation and the size, complexity and time period of the project in question.

The SCL determines 6 methods to select from, which are variants of prospective and retrospective. Below is their table of Delay Analysis methods:

The choice of technique is critical to the outcome.

Disruption

Disruption, as opposed to delay, can be defined as the loss of productivity in that the Contractors resources are not working at their correct output and therefore have a reduced efficiency. This is distinct from 'production' which is a measure of how much work is done regardless of the resources used.

The Contractor is entitled to be paid their actual costs for disrupted work over and above the value of the work.

To measure the loss of productivity the SCL protocol defines various methods of 'Disruption Analysis'.

Measured Mile

The SCL confirms that the most widely accepted method of calculating disruption is the 'Measured Mile' analysis. This involves the comparison of work that was subject to disruptive events, with similar work that was constructed without hindrance. This therefore has the advantage of removing any tender or planned assumptions that could not be achieved but instead it uses the actual performance of the Contractor as its baseline.

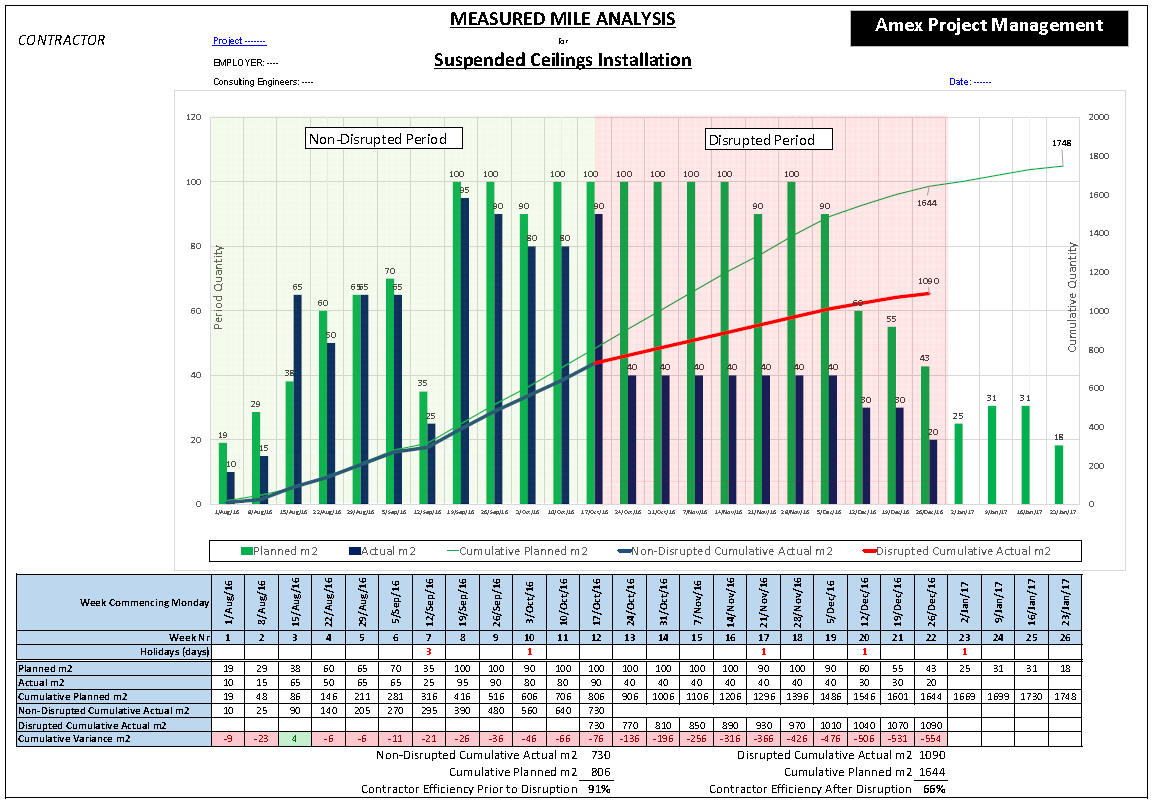

Take for example a contract to install suspended ceilings in a hotel that suffered disruption due to adjacent delays in MEP works. The Measured Mile procedure would be:

Planning Stage

- Produce and agree a baseline programme with resources loaded;

- Monitor this programme with actual work achieved on a weekly basis;

- Compile records of actual work achieved and submit them to the responsible person;

- Compile records of any delays that occur and issue notices;

Dispute Stage

- From the updated programme, produce a planned v actual output schedule and demonstrate in a graph;

- Demonstrate the actual production achieved prior to any disruption events occurring;

- Demonstrate the actual production achieved during any disruption events occurring;

- Calculate the rate of productivity in the non-disrupted period;

- Calculate the rate of productivity in the disrupted period;

Calculate Compensation

- Gather actual costs for the non disrupted period;

- Calculate the difference in productivity and multiply this by the quantity achieved in the disrupted period.

Therefore:

The Contractor installed 730m2 of ceilings from a planned 806m2 and was therefore working at 91% productivity prior to the disruption period.

In the disrupted period the Contractor installed 360m2 from a planned 914m2 and was therefore working at 39% productivity during the disruption.

The actual hours spent in the first period should be obtained.

For example if the Contractor had 4 operatives deployed for 40 hours a week then he spent 4 x 40 x 11 = 1760 hours. Therefore their productivity was (1760/730) = 2.41 hours/m2.

In the disrupted period, which in this case is the same duration, the Contractor achieved 360m2 for the same expenditure of 1760 hours. Therefore their productivity was (1760/360) = 4.89 hours/m2.

Assuming the same resources are used, the shortfall of (4.89-2.4) of 2.49 hours x 360 should be compensated to the Contractor at his actual labour rate plus an allowance for overhead and profit if the contract permits.

Earned Value and Programme Analysis

If the data required for the production of the measured mile calculation is not available, say if the project was in the early stages or in a new distinct phase of work with no comparable activities, then a different method is required.

The SCL protocol prescribes 2 other methods being Earned Value Analysis and Programme Analysis, these methods are similar in nature. The Programme Analysis is an extension of Earned Value Analysis and involves the comparison of the actual work with some theoretical output usually the agreed programme but can be related to output on other similar projects.

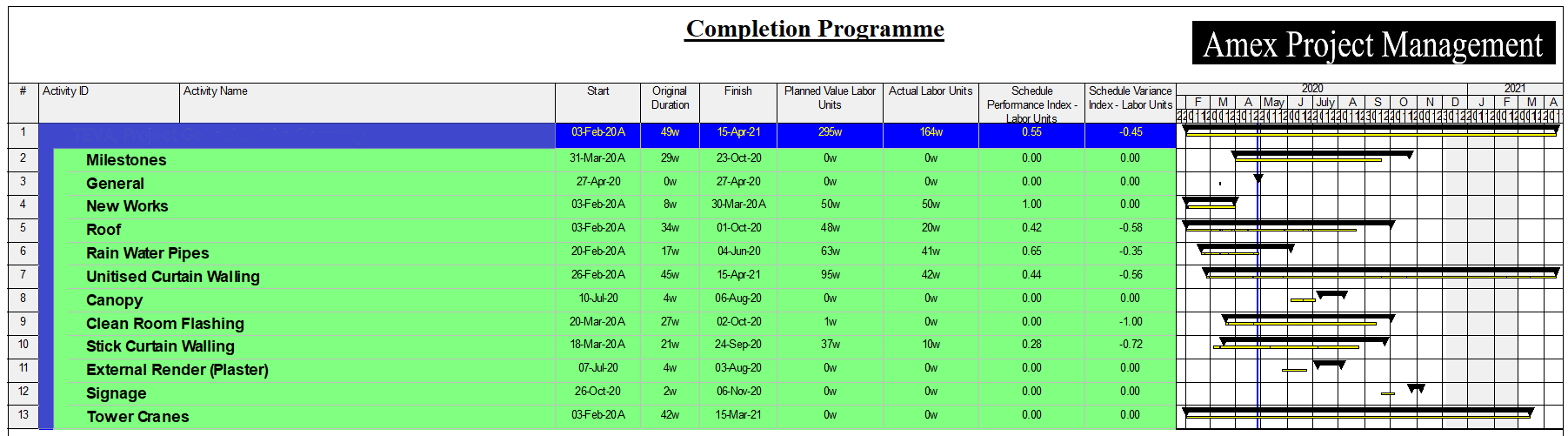

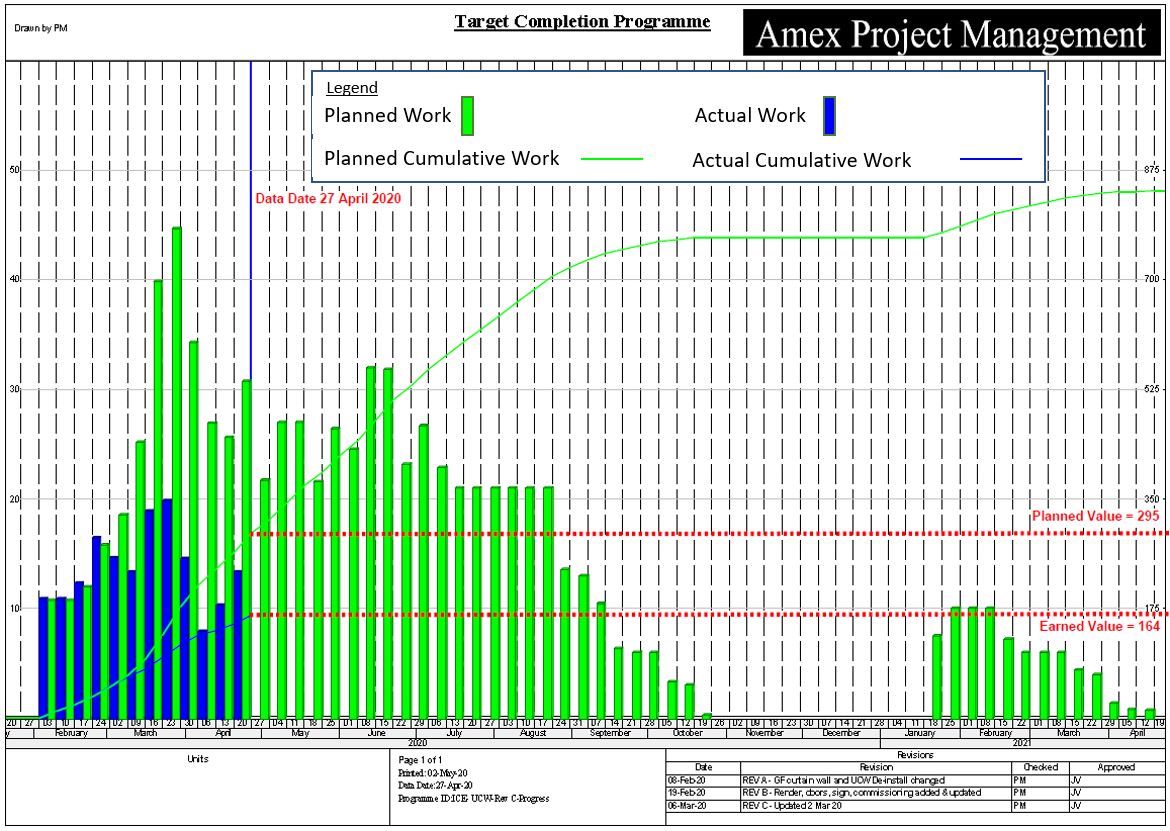

In the example below a sub contract for various works was disrupted and the previously agreed programme was updated to reflect actual work achieved.

The programme was labour loaded and therefore the earned value is automatically calculated by the software from the updated progress. The columns below show the information as;

Planned Value Labour Units 295, Actual Labour units 164, Schedule Performance Index 0.55, Schedule Variance Index 0.45.

When graphed the data looks like this:

The earned value of 164 labour units, when compared to the planned value of 295 labour units provides a Schedule Performance Index of 0.55 or 55%.

The earned value of 164 labour units is then compared to the actual labour units spent on the project.

For example if the Contractor deployed the required number of labour units at 295 then the shortfall in output of 131 labour units should be compensated to the Contractor at his actual labour rate plus an allowance for overhead and profit if the contract permits.